NextGen 16ft Skiff

BACKGROUND

In late 2023, Damic Design was commissioned by the Manly and Belmont 16ft Skiff Clubs to lead the design and production rollout of a new 16ft skiff. The objective was to meet the increasing demands of Australian 16ft skiff sailors for improved supply capability, enhanced build quality, and elevated performance standards.

While the original Craig Hughes / ASSA one-design hull was retained with minor refinements, the primary development focus centred on a new deck design. Significant reduction in manufacturing complexity was achieved while introducing greater flexibility in configuration, allowing sailors to tailor setups to their individual preferences.

To support long-term consistency and production excellence, the clubs invested in precision carbon tooling. This ensures durability and uniformity across all builds, utilising the latest pre-preg carbon fibre manufacturing processes.

Some of the key features include:

Easy integration of a spinnaker chute as an upgrade option

Hidden control line take ups for a clean and modern deck layout

Strong emphasis on improving hull stiffness with class leading quality control measures

Moulded kick-off bars that extend further aft for improved ergonomics

KEY INFORMATION

Financially backed by joint partnership between Manly and Belmont 16ft Skiff Clubs, endorsed by ASSA

Australian made by the building partner (Van Munster Boats)

Design work by Luka of Damic Design

Key decisions by Manly/Belmont Partnership Committee

With design work and tooling now completed, the project is in the hands of the clubs who are arranging for production to commence as soon as practically possible.

Skiff floor plug machining - Nov '24

Skiff deck plug after rough finish - Nov '24

Skiff deck plug complete - Dec '24

Skiff hull plug complete - Dec '24

Skiff hull plug delivered - Dec '24

Hull plug prep before layup - Mar '25

Cockpit floor mould - Mar '25

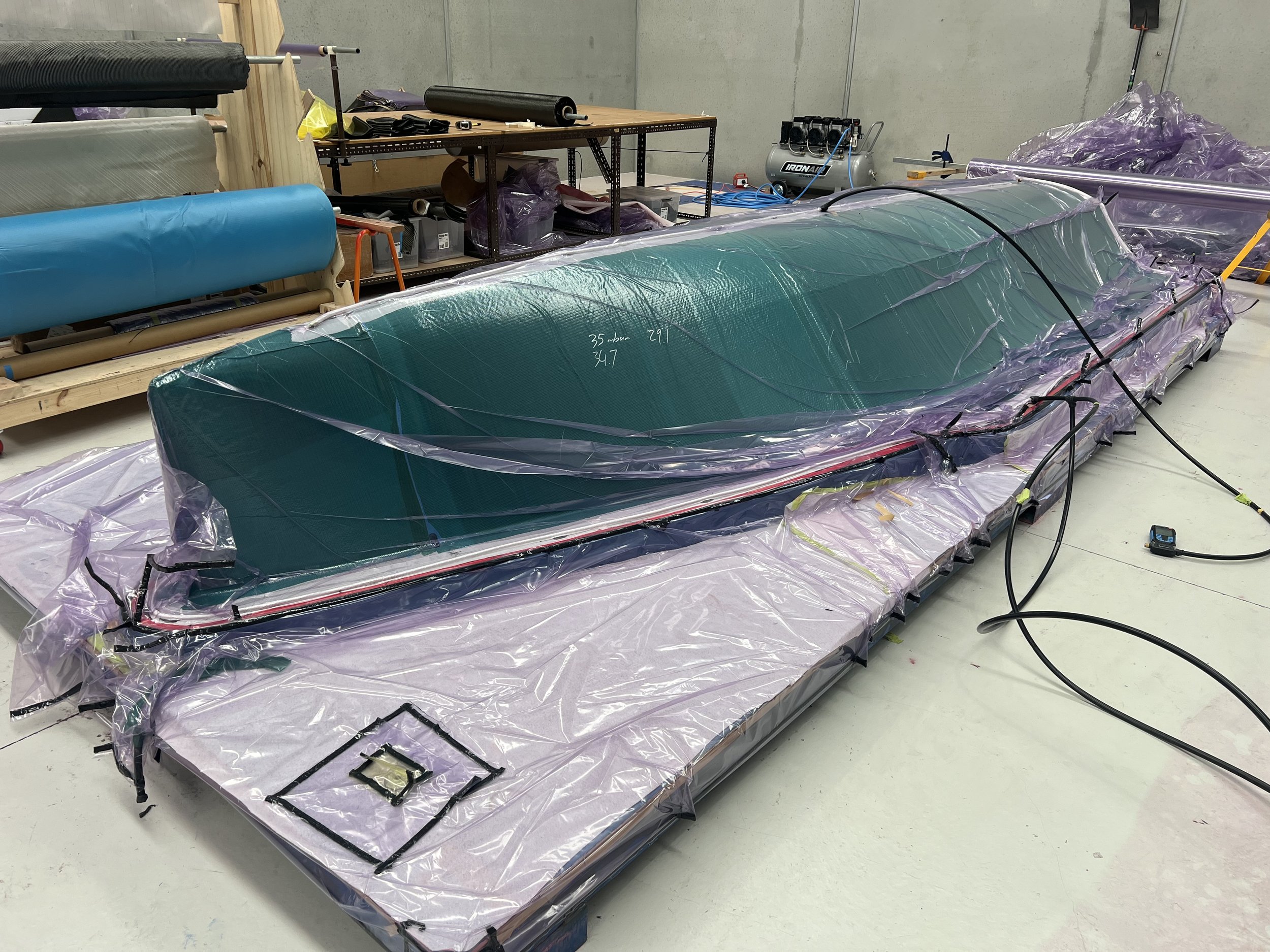

Hull mould infusion - Mar '25

Hull mould nearing completion - Apr '25

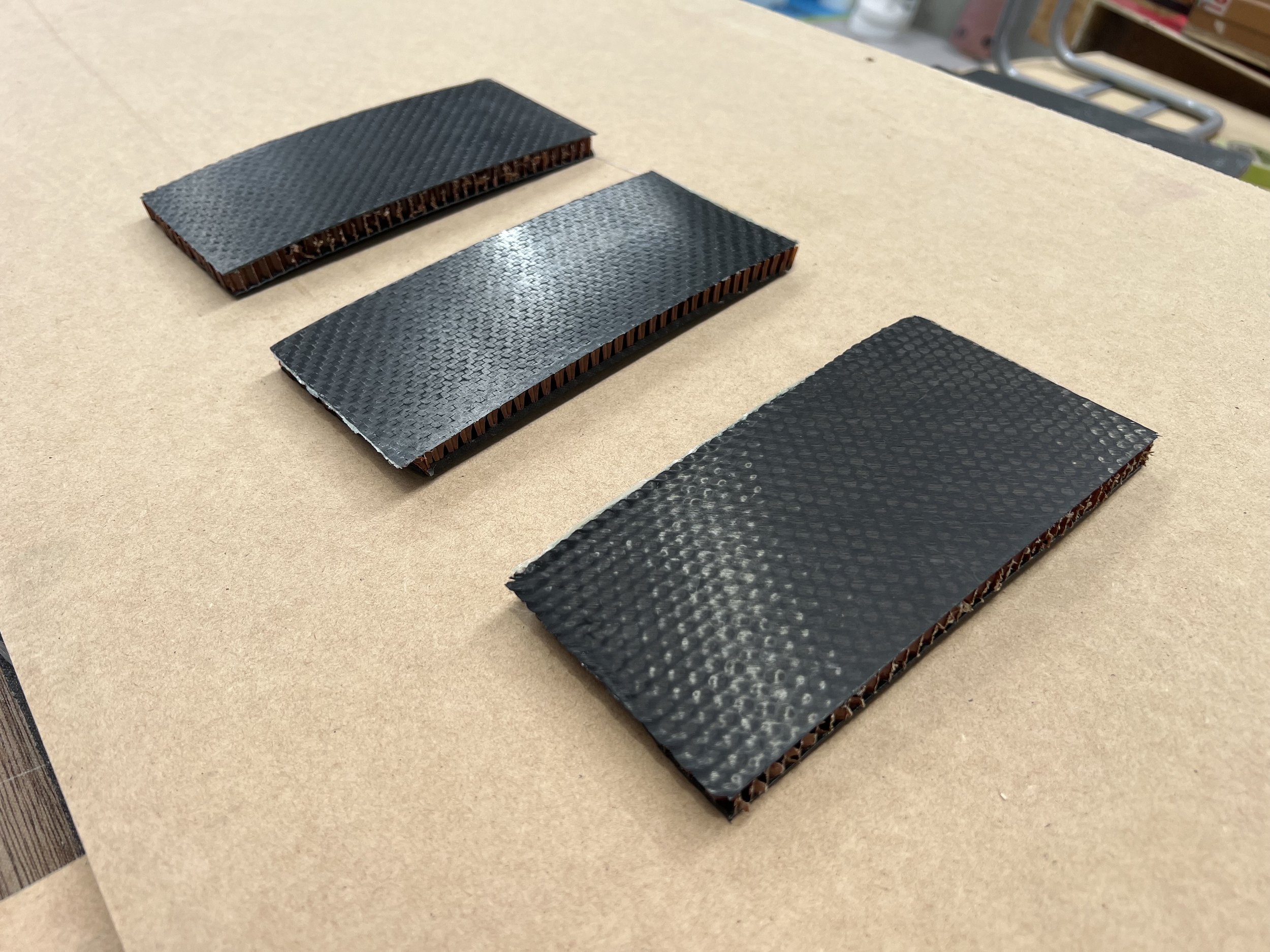

Nomex/Carbon panel samples for prototype - Apr '25

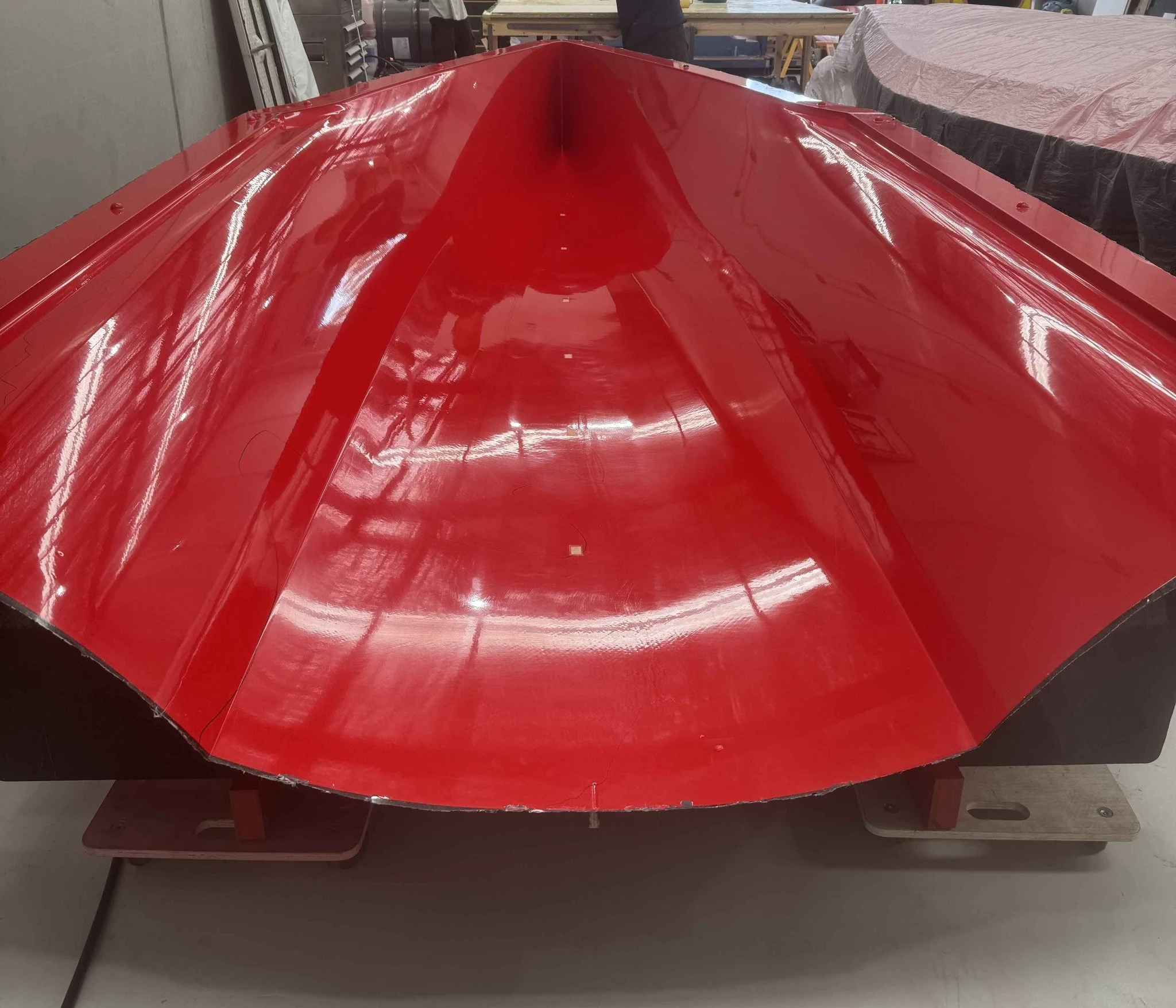

Finished hull mould - April '25

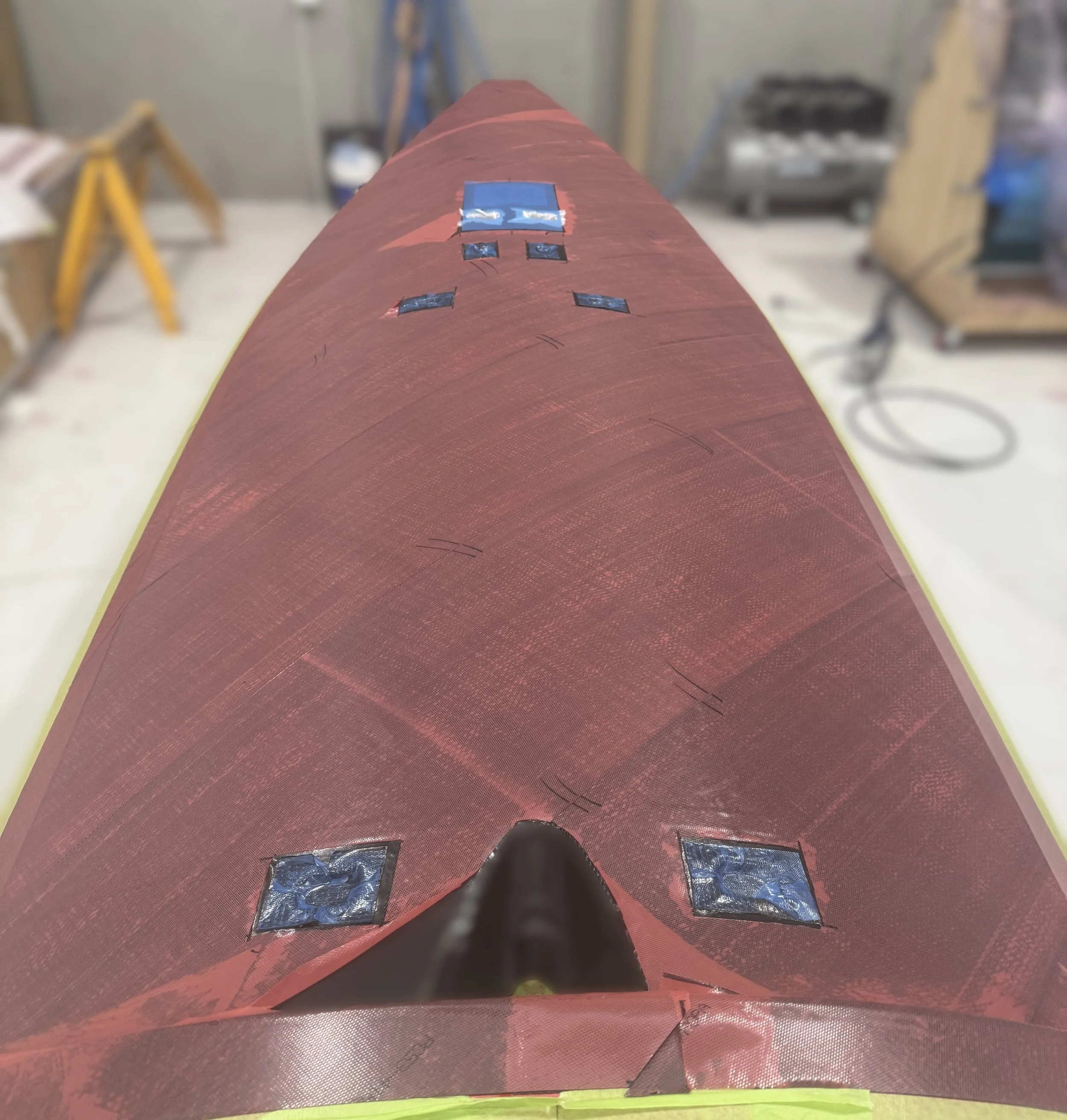

Hull layup - May '25

Floor skin & solids - May '25

Hull outer skin - May '25

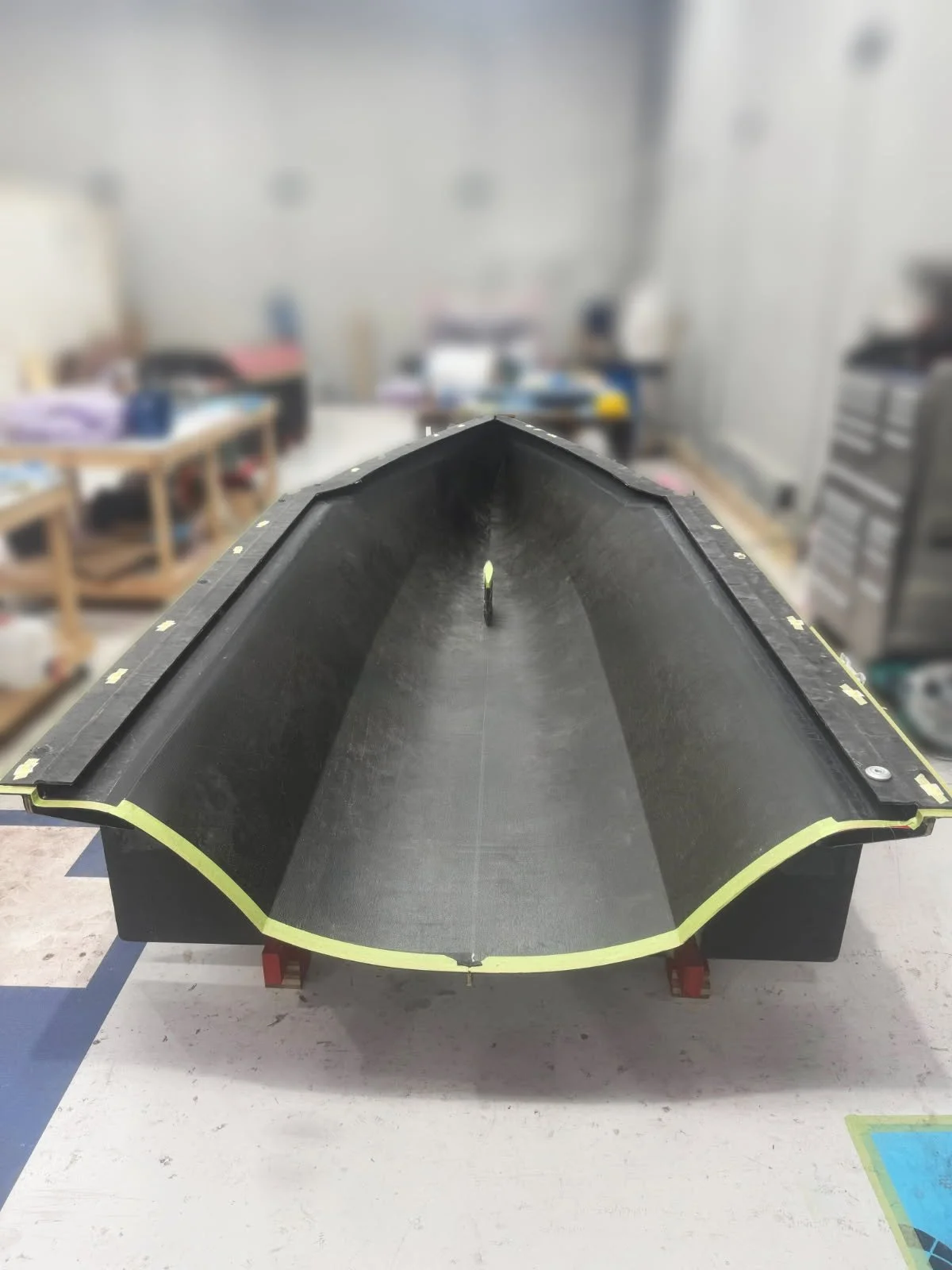

Hull shell complete - June '25

Floor de-moulded - June '25

Hull with frame layout - June '25

Prototype testing - Sep '25